EDI vs. API: Which One Is Right for Your Supply Chain Integrations?

Supply Chain Management and Data Dependency

The supply chain industry is heavily reliant on timely and accurate data interchange, so the goods can be moved from and to the correct destination safely. An effective supply chain must have data interchange in place from container tracking to inventory management and everything in-between. There are two primary technologies that are used to exchange these massive quantities of data: Electronic Data Interchange (EDI) and Application Programming Interface (API). As APIs have become more prevalent in the supply chain industry, business leaders find themselves weighing the pros and cons of EDI vs API as their method for data interchange.

What are EDI and API?

Both an EDI solution and an API integration are used to transmit information from business-to-business and business-to-customer. While they both perform the same interchange of data, there is a significant difference between EDI and API. Leveraging the right technology can generate innovation and create resilient supply chains.

EDI integration has a longstanding history. Developed in the 1960s, EDI technology has been used to standardized transactions between customers and vendors for decades. EDI provides information from one system to another in a text-based format. This supply chain integration has stringent requirements for what kinds of data can be put into each field. Vast quantities of data can be passed through an EDI due to the text-based nature of the data, and the strict rules for data input ensure clean, accurate data is transferred from system to system.

API is a newer technology, emerging in the early 2000s with Salesforce and eBay being early adopters. APIs have only grown in popularity since then, becoming more and more prevalent across all industries—including supply chain. An API is a more flexible exchange of data than an EDI. With a well-designed API, the business can make an API call and send or receive the specific data they want. APIs aren’t solely text-based, and an API call can have one of four objectives: to request data, send data, revise or add to existing information, or delete existing information.

EDI vs API Use Cases in Supply Chain

With the increased flexibility of API, it may seem like an API is the natural choice for your supply chain integrations. However, that won’t always be the case.

EDI data is still found in supply chains globally. Because the EDI system has been around for considerably longer, many big box retailers and other large businesses run data exchange based solely on EDI integration. When working with these larger retailers, it’s important to use an EDI connection as that’s how the data is already organized.

APIs can be used for a variety of supply chain integrations and offer enhanced security and specificity over EDI integrations. Ecommerce brands are rapidly adopting API integration for their vendors due to the increased flexibility and immediate feedback. An API integration can send or call values of all different varieties and can be customized to function between any two systems.

Both EDI and API are used in distribution and fulfillment settings to acquire order numbers, send shipment and tracking information, manage inventory levels, and more. While API offers a more modern and user-centric option, it’s unlikely that API will entirely replace EDI. Large companies that are reliant on EDI will continue to require use of EDI for their distribution and fulfillment supply chain integrations.

Transitioning to “API First” in Supply Chain Integrations

As early as 2020, 83% of surveyed technology professionals stated that API integration is a “critical part of their business strategy.” The supply chain industry has lagged in this aspect of digital transformation but is beginning to adopt an “API-first” development approach.

With big box retailers continuing to use EDI systems for data exchange, the supply chain industry didn’t have much impetus to rush the transition. However, as e-commerce has continued to grow, API development has become significantly more important. In fact, in 2023, over 20% of retail purchases were made on ecommerce platforms. By 2026, it’s expected that this percentage will grow to 26%. As these statistics continue to grow, the industry is taking notice and working to include API-first development throughout supply chain integrations.

With an API-first development approach, the creation and use of APIs occurs before any other components of an application, and before any other data exchange methods are built.

This approach provides several benefits to development teams and end-users:

Scalability

A system designed with API at its core is easily scalable. Additional servers and services can be added as needed, and resources can be managed more effectively. Adding new pieces of data for exchange in your API can be a simple modification, decreasing development workload.

Security

Due to the nature of API calls, in which specific people have access to call upon the API, security is heightened. Authentication, authorization, and many other security measures are available at the API level—enabling a high level of protection for the data and application.

Flexibility and Adaptability

Designing API-first allows for changes to be made to the application implementation without affecting any external systems or other application components. This flexibility allows companies to adapt to changing requirements and technologies without having to adjust entire applications.

Testing and Debugging

API systems can be evaluated independently of the application’s user interface. This makes it easy to identify and fix any bugs in the development process and enhances the overall reliability of the software.

Documentation and Communication

API-first development necessitates clear, comprehensive documentation on the interactions between different systems. Developers can reference this documentation, and it can be useful to facilitate cross-functional collaboration.

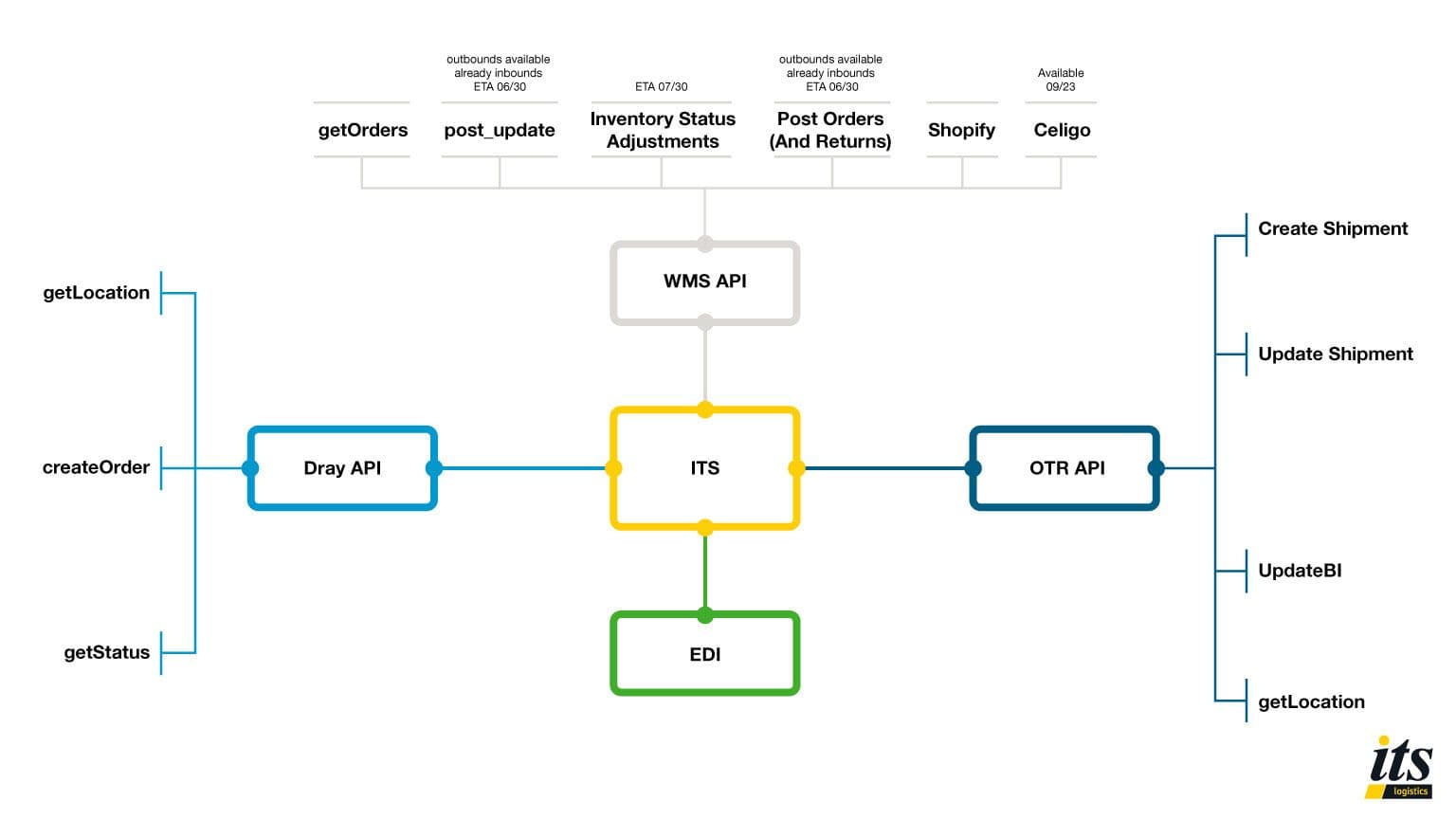

ITS API Ecosystem

API-First and ITS Logistics

ITS Logistics is committed to implementing the most up-to-date technology for customers across North America and is leading the transition to API-First development. Evolving to better meet the needs of e-commerce customers, ITS Logistics has also recently developed and released an API for customers to seamlessly integrate to the systems used in distribution and fulfillment. Both the transition and API development have customers looking forward to shorter implementation timelines, increased flexibility for data exchange, enhanced security, and more.

Development will be supported at all times during the company’s partnership with ITS. At the beginning of the engagement, the in-house, US-based development team for ITS Logistics will do a systems discovery and requirements call. The expert team will identify what kinds of supply chain integrations are needed, and how best to leverage API-first development.

Looking for a new, technology-forward distribution and fulfillment partner? Call ITS Logistics today at (775) 574-4278, or contact us online to speak to one of our distribution and fulfillment technology experts.