Reviewing the 2023 Peak Season

Peak season 2023 has come and gone, and the ITS Logistics leadership shares their thoughts and insights of how this peak was different than years past. In addition to this, thoughts on planning for peak season in 2024. In the face of shipping bottlenecks, port labor strikes, rising fuel expenses, and a supply and demand imbalance, the logistics industry has experienced an overall "slowcession”. Despite these challenges, ITS offered solutions for its customers by focusing on smart labor planning, using industry insights from previous years, and coming up with creative logistics solutions. These thoughtful efforts guaranteed customer satisfaction, the smooth processing and delivery of packages to consumers.

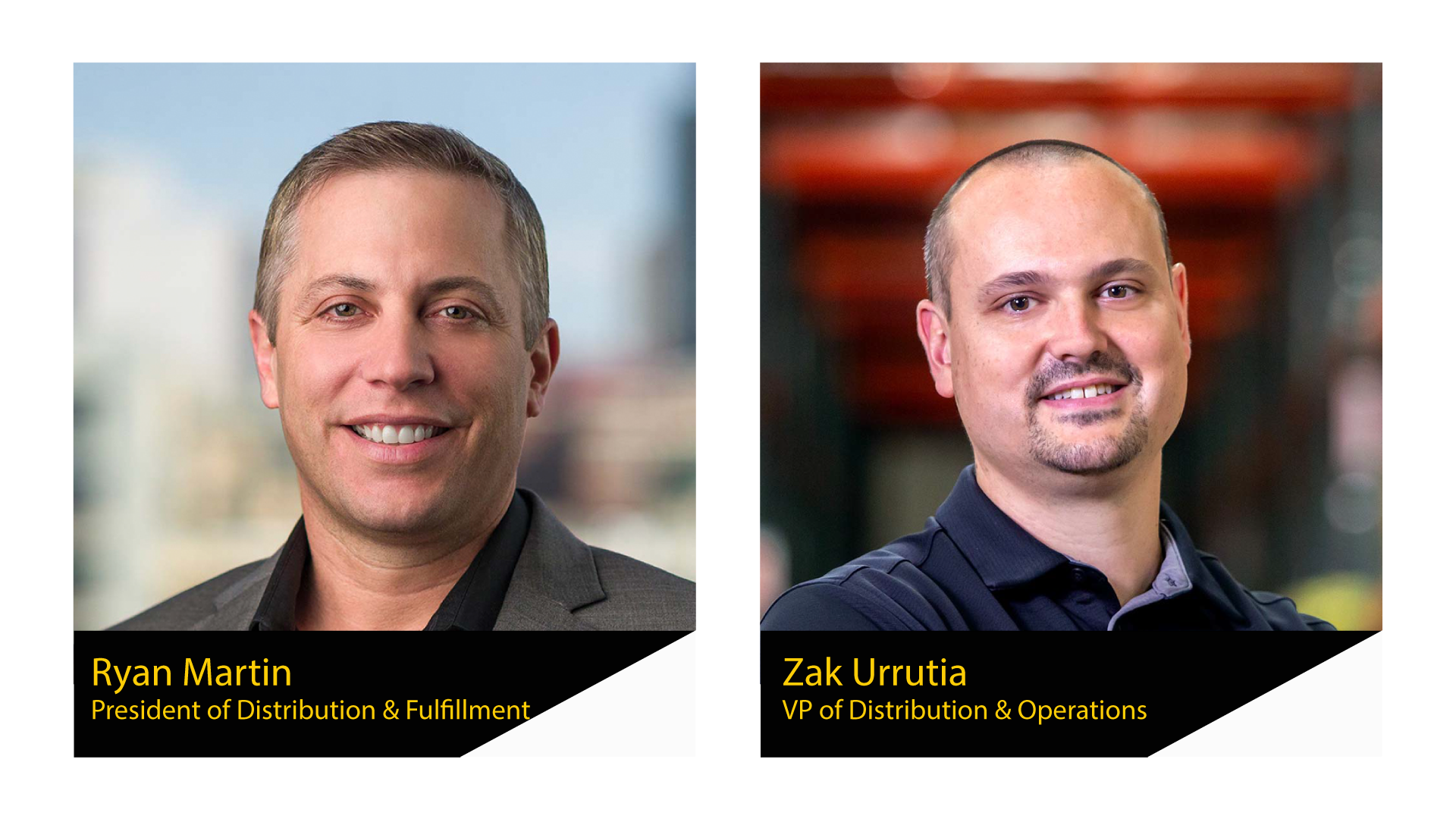

A Q&A with ITS Logistics Leadership

What worked best this past peak season?

ZU: “If you can look back after a peak season and feel good about controlling the operational elements that you can directly influence, there’s bound to be some success stories to lean on. 2023 provided the opportunity to reclaim some control in areas that were more challenging at the macro level in prior peak seasons.

Successfully implementing strategies for labor planning, systems scaling, and collaboration with external partners during peak measured the effectiveness of pre-peak planning. Overcoming unexpected surges or lulls in volume, depending on the type of product was also made significantly easier if the proper plans were in place.” We performed well in these areas, and that’s something to be proud of.

RM: “Our preparation and planning this year were likely the best in terms of labor and equipment planning. The peak we experienced was successful, thanks to thorough preparation. Staffing worked effectively, enabling us to secure the required personnel on time. Unlike the previous peak season, where getting people in was a challenge, especially since 2020, our staffing providers successfully met the quota we assigned them for this holiday season.”

What didn't work this past peak season?

ZU: “Every peak shipping season provides an opportunity to learn and better prepare for what comes next. There are always opportunities to dig deeper, even in longstanding and established operations. To understand the subtle variances and nuances that often change from year to year. Small changes in buying habits or sales and marketing strategies can create a need for incremental, but critical, adaptations in strategy to ensure a smooth customer experience. You really can’t have too many conversations with your customers in advance of peak when planning and understanding are the focus.”

RM: “There were some system glitches for external systems. There were some issues which were a definite challenge. It hampered us within a couple of accounts... For this peak we were onboarding a relatively large customer which also took a lot out of us during that busy period. It was one of the largest and most complex customers we have ever onboarded, and we had to do it in a very abbreviated time frame.”

What would you change if you could redo the 2023 peak season?

ZU: “If we had the luxury of taking all our learnings and historical data from the end of this peak season back to the beginning, we’d obviously be able to ask ourselves the ‘perfect’ questions. I believe the key changes lie in thoroughly understanding the subtle shifts in consumer and seller behavior in 2023. Many intentional strategies were employed by both groups to capitalize on the peak in a year where cost remained a significant focus. Small changes to otherwise sound operational processes could obviously result in a near-perfect customer experience during busy season.”

RM: “One change we would make is adjusting shift schedules in specific operations to provide team members with more breaks. While our peak season was generally positive, there were some areas in certain buildings where improvements to the shift schedule could be made. We doubled our distribution and fulfillment footprint in the last year so this was this first time we were coordinating across three different campus locations (Reno, Indy, and Dallas).”

What is your outlook for 2024?

ZU: "Lingering uncertainty seems more common these days than an exception. Macro-economic doubts and cautionary tales, both optimistic and pessimistic, fill the headlines as we enter 2024. Emphasizing operational excellence, precision in customer service, and the ability to scale each focus will help to provide the flexibility needed for success in the coming year.”

RM: “I expect things to stay relatively the same except for a potential shift towards more promotional-based customer behavior, with consumers leaning towards spending on sales. This pattern was evident during the recent peak season, marked by a strong Black Friday and Cyber Monday followed by a slowdown, resembling the pre-pandemic flow. Unlike the consistent post-pandemic peak, the upcoming year remains uncertain, but it might align with the trend of being more promotion focused.”

Why ITS

ITS Logistics offers 3.7M square feet of distribution and fulfillment space across three US regions: Reno, NV, Indianapolis, IN, and Dallas/Ft. Worth, TX.

Indiana, a crucial shipping hub, features three maritime ports and the only statewide port system with access to both U.S. coasts. Hosting the world's second-largest FedEx hub, it's strategically connected to the largest U.S. rail hub in Chicago, just three hours away. Indiana also boasts the UPS Worldport Air Hub, ranking as the fourth busiest cargo airport globally and the second busiest in the U.S.

The newly established ITS facility in Dallas/Ft. Worth, TX, positions itself for future expansion. It provides convenient access to the U.S. supply chain infrastructure and labor market. This facility empowers ITS to integrate various regional trucking operations, including dedicated contract services, drayage, line haul, expedited services, storage, drop trailers, rapid replenishment fulfillment, transportation, and special projects/warehouse moves.

ITS stands out as a leading third-party logistics company, strategically positioned to offer distribution and fulfillment services that can reach 95% of the population within two-days. The company’s warehouses are certified by AIB, equipped with cutting-edge technology, and manned by skilled staff— ensuring its ability to meet and exceed all fulfillment requirements.

- Learn how Wellness Pet Company scaled their supply chain operations to meet unprecedented demand.

- AHF Products® Forecasts $600,000 in Savings in First Year of Partnership with ITS Logistics.

- Caraway Sees 280% Order Volume Increase and Expands into Omnichannel Fulfillment.

How can we help you?